Eight departments issue document to promote comprehensive use of industrial resources

The Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Science and Technology ···

Fujian Vinking Machinery Co.,Ltd is located in Quanzhou, the first East Asian cultural capital. We are committed to forming, curing and packaging high end concrete product. We have gathered the latest technology and productivity from home and abroad to provide customers with best solutions.

The unity of “Vinkinger” and our resilience have led to the establishment of a team of professional engineers who have gradually developed our own core technology with our strong research and development capabilities and innovative spirit.

With a legacy of glory, Vinking continues to develop with the recognition of the industry and society.

Forest Press Hydraulics Hermetic Press

Europe's leading hermetic press machine, FOREST PRESS HYDRAULICS, has been bringing its products and services from the UK to continental Europe to the world since 1984, specialising in hermetic press wet mix kerb/slab making, a heavy duty machine designed ahead of its time and proven in different climatic conditions around the world.

1. VK600 automatic block making machine is an economical machine developed and produced by Vinking Machinery. It uses 360° fast feeding system, shorter forming cycle and higher production efficiency.

2. VK900 automatic block making machine forced synchronous vibration system can be adjusted through Siemens frequency conversion technology, vibration excitation force, the use of steel transmission, no kinetic energy loss and can ensure accurate synchronization, less energy consumption, better vibration effect.

3.VK1200 automatic block making machine combines the advantages of VK900 and VK600, and by optimising the design, the mould is easier to combine for the number of modules and pendulum blocks for the production of products, and is more flexible for the matching mode of the production line, which can be an economic mode with a selected layout, and also suitable for the fully automatic production line mode.

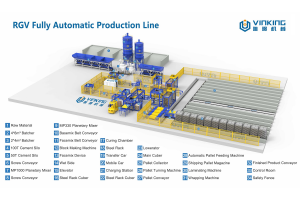

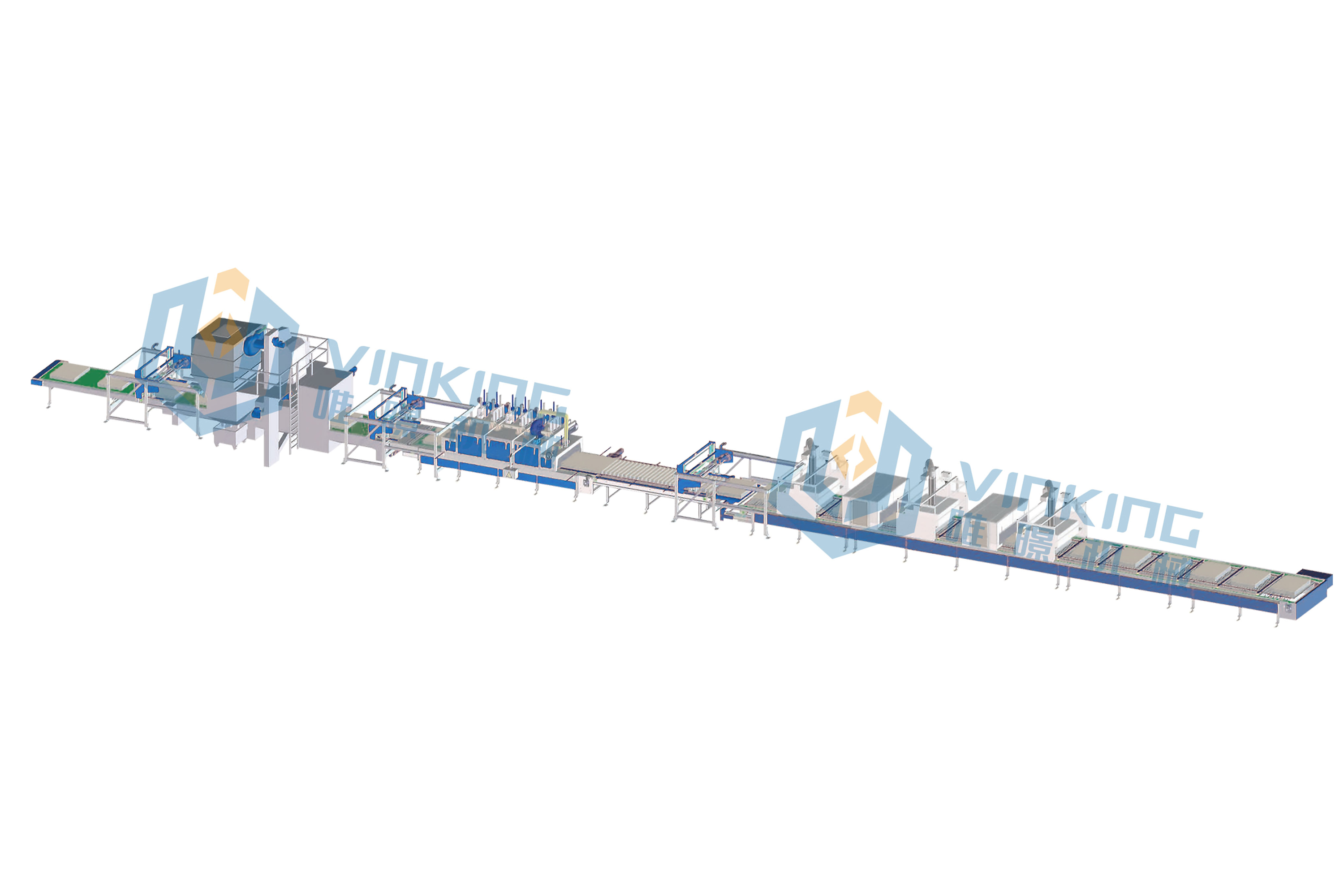

We have developed and produced different types of block making machine to suit different customer’s requirements. Automatic RGV transfer car system can be with or without steel curing rack to improve the block making process and provide a better solution for our customers to produce higher standard concrete products.

Design: Determining the product, Confirming mould drawing, Preparing the material.

Production: Processing, Assembling, Heat treatment, Welding, Matching, Painting, Packing.

Quality Checking: Quality inspection of work-in-process, Quality inspection of finish product.

lNo Shipping Pallet

lForklift Hole

lAuto Cubing With Rotation

lLess Damage Rate

lLaser Position

lFlexible Pallet Size

lFrequency Control

lStable Cubing

lServo Motor

1.Batcher

2.Planetary Mixer

3.Automatic Pallet Feeding Device

4.Water Curing Lifting Device

5.Strength Testing Machine

6.Four Side Clamp, Two Side Clamp With & Without Rotation

7.GMT Pallet With & Without Steel Reinforcement (Galvanized Steel)

1.Machanical Parts: Siemens, SEW, ABB, HARDOX, Air TAC, Oli-Wolong, etc.

2.Electric Parts: Siemens, Schneider, Omron, ABB etc.

3.Hydraulic Parts: Taiwan Yuken, Italy Manuli, HAWE, Rexroth, etc.

SURFACE TREATMENT PRODUCTION LINE

1 IR preheating station

2 Spraying – primer

3 IR heating station

4 Spraying – sealer

5 IR heating station

(Coating line modular extendable with IR and/or UV stations)

(Instead of spraying, roller coating is also possible) depending on the coating agents used)

Vinking Machinery independently develops and produces different models of concrete block making machine adapted to different capacity requirements for investment, with automatic RGV transfer car system, new energy transfer with steel curing rack, improving the block making process and providing more quality concrete product production solutions for our customers.

1.Main Frame Adopt Germany Standard

2.Efficient Vibration Technology

3.Fast Feeding Car

4.Intelligent Frequency Conversion Technology

5.Siemens Control System

6.Servo Hydraulic System

18 oversea offices in 6 global market:

Africa Region: Egypt, Nigeria, Kenya, South Africa

Middle East: UAE, Saudi Arabia, Iraq

South Asia: India, Pakistan

Asia: Philippines, Vietnam, Thailand, Indonesia

Latin America: Mexico, Brazil

Europe and America: UK, USA, German

Fujian Vinking Machinery Co.,Ltd, dedicated to high-end concrete manufacturing machinery, excellence, established to serve more than 30 provinces and area in China.

Integrated R&D and production services by an elite team

Pre-sales service, in-sales service and after-sales service

All-round service for customers

Watch out for more of Vinking's global exhibitions and come and see the latest innovations at Vinking.

Vinking is working with many partners around the world to build a new intelligent ecosystem that will drive technological breakthroughs and innovation in the precast concrete industry.

Follow the industry news, never stop on the road of exploration and innovation.

Fast communication with customers and zero distance service, just to work with you to win together.

Respecting talent, retaining talent, using talent, creating first-class talent, creating first-class enterprises.

If there is anything we can do for you, most welcome to contact us by whats’ app, E-MAIL etc 24 hours. We will reply to you as soon as possible.

From Bricks and Tile Magazine

1 Preface

Coloured concrete pavement blocks are also known as pavement blocks. In recent years, the production and application of coloured concrete paving blocks has flourished with the construction of municipalities and buildings in China. The combination of slab shape and colour creates a unique and pleasing coloured pavement, which contributes positively to the beautification of urban roads. However, the current production of coloured concrete pavement blocks has problems such as alkali flooding, varying shades of colour and uneven surfaces, where the quality of the colour is the key to its decorative effect. The following is a discussion of the factors that affect the quality of concrete pavement blocks, and proposes measures to prevent and control them.

2 influence concrete pavement brick colour quality factors and preventive measures

2 .1 The influence of the water-cement ratio on the quality of the colour

2 .1 .1 Causes :

①After the concrete has hardened, some of the excess water evaporates out of the concrete and forms pores, which are very small and numerous and scatter the incident light, resulting in a lighter concrete colour. The higher the water to ash ratio, the lighter the concrete colour;

② In the process of producing the same batch of concrete pavement blocks, the water-cement ratio is arbitrarily changed, so that the colour of the produced pavement blocks varies, resulting in unevenness.

2 .1 .2 prevention and control measures:

① choose the best concrete ratio and water-cement ratio, that is, forming conditions allow, try to reduce the water-cement ratio, so that the production of the product is dense, the concrete in the capillary pore is less, the less bubbles produced;

② Strict control of sand and stone moisture content, to ensure the accuracy of water-cement ratio control. At the same time, in the process of producing the same product, the water-cement ratio cannot be changed at will.

2 .2 The influence of cement colour on colour quality

2 .2 .1 Causes:

(1) The large specific surface area of cement, the large quantity used and the inaccurate measurement can cause different shades of colour in each batch of material, and the colour of the products produced will be uneven;

② The colour of silicate cement, whether light grey or dark grey, will have a weakening effect on any colour. For dark colours (red, brown, black, etc.), the use of grey and white cements has little effect on the colour quality of the products; for light colours (yellow, green, blue, etc.), the effect of the colour of the cement is greater.

2 .2 .2 Prevention and control measures:

① Cement measurement should be accurate, the general cement measurement error should not be greater than 1%, and the measurement scale should be regularly calibrated;

The lighter the colour of the grey cement, the more vivid the colour of the product, so light-coloured cement or white cement should be used as far as possible, and the same type and batch of cement should be used to produce the same batch of concrete road block products.

2.3 The effect of pigment quality and admixture on colour quality

2 .3 .1 Causes:

① Concrete pavement blocks produced in the same batch have a large colour difference, the colouring ability is not strong, and the pigment is not evenly dispersed;

② inaccurate pigment colour matching. The more pigments, the darker the product, which affects the physical and mechanical properties of concrete pavement blocks and increases the cost of the product.

2 .3 .2 Prevention and cure measures :

① synthetic iron oxide pigment coloring ability is strong; natural iron oxide pigment, coloring ability is not strong, should choose to use synthetic mineral pigment;

②When the pigment doping amount in the product reaches a certain value, then increase the doping amount, the colour of the product will no longer improve. General iron oxide pigment saturation point doping for 4 % to 8 %. If the pigment with poor colouring power is used, the saturation point of the pigment is also increased, and more dosing is needed to achieve the required colour effect;

③ Ensure the same mixing time for the same batch of pigments, usually 0.5 to 1 min. It is also possible to add dispersant to make the pigments evenly mixed and dispersed.

2.4 Influence of forming parameters on colour quality

2 .4 .1 Causes: vibration time and vibration force forming parameters are different, to the concrete pavement brick surface brings different spots, which will cause different degrees of light scattering, so that the colour products vary in shade.

2 .4 .2 prevention and control measures:

① the same batch of products used in the best vibration time and vibration force and other molding parameters should be the same, can not be arbitrarily changed in the middle;

② Trial production of solid specimens on the forming machine, to obtain the best forming parameters for each, so that the concrete forming to achieve the best density.

2.5 Influence of maintenance temperature on colour quality

2.5.1 Causes: The effect of maintenance temperature on the colour of concrete pavement blocks is mainly due to the thermal stability of the pigments themselves, which can vary greatly when heated. The higher the curing temperature, the lighter the concrete itself.

2 .5 .2 Prevention and treatment measures:

To prevent steam condensation from contaminating the surface of the product during low temperature maintenance, cover the decorative surface with plastic sheeting;

② Establish a good maintenance system to ensure the consistency of colour quality.

3 Conclusion

The production of uniformly coloured, brightly coloured concrete paving blocks is a systematic project that is carried out throughout the entire production process. There are many factors that affect the colour quality of concrete pavement blocks, including the quality of raw materials, mix ratio and measurement, forming and maintenance. Only through comprehensive management can the colour quality of concrete pavement blocks be guaranteed. At the same time, a quality assurance system and related rules and regulations are set up to establish operating procedures for each process, and each production department and management department pay attention to the quality of the product, so that the colour of the concrete pavement blocks produced can be of good quality and play a colourful and decorative role.

Eight departments issue document to promote comprehensive use of industrial resources

The Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Science and Technology ···

Factors affecting the colour quality of concrete paving blocks and measures to prevent and control t

At present, China's investment in the field of green environmental protection continues to increase, all kinds of environmental protecti···

营销热线:+86 136 7590 9717

联系电话:0595-86799877

公司传真:0595-86766877

公司邮箱:vinking@vkmachine.com

公司地址:福建省泉州市南安市滨江工业区滨江大道17号

Copyright @ 2021 . 福建唯暻机械有限公司. ICP证:闽ICP备2021007924号-1