- About Us

About Us:

Fujian Vinking Machinery Co.,Ltd is located in Quanzhou, the first East Asian cultural capital. We are committed to forming, curing and packaging high end concrete product. We have gathered the latest technology and productivity from home and abroad to provide customers with best solutions.

The unity of “Vinkinger” and our resilience have led to the establishment of a team of professional engineers who have gradually developed our own core technology with our strong research and development capabilities and innovative spirit.

Values: Quality, Service

Vision: We Deliver Concrete Promise

With a legacy of glory, Vinking continues to develop with the recognition of the industry and society.

- Products

Products:

Forest Press Hydraulics Hermetic Press

Europe's leading hermetic press machine, FOREST PRESS HYDRAULICS, has been bringing its products and services from the UK to continental Europe to the world since 1984, specialising in hermetic press wet mix kerb/slab making, a heavy duty machine designed ahead of its time and proven in different climatic conditions around the world.

1. VK600 automatic block making machine is an economical machine developed and produced by Vinking Machinery. It uses 360° fast feeding system, shorter forming cycle and higher production efficiency.

2. VK900 automatic block making machine forced synchronous vibration system can be adjusted through Siemens frequency conversion technology, vibration excitation force, the use of steel transmission, no kinetic energy loss and can ensure accurate synchronization, less energy consumption, better vibration effect.

3.VK1200 automatic block making machine combines the advantages of VK900 and VK600, and by optimising the design, the mould is easier to combine for the number of modules and pendulum blocks for the production of products, and is more flexible for the matching mode of the production line, which can be an economic mode with a selected layout, and also suitable for the fully automatic production line mode.

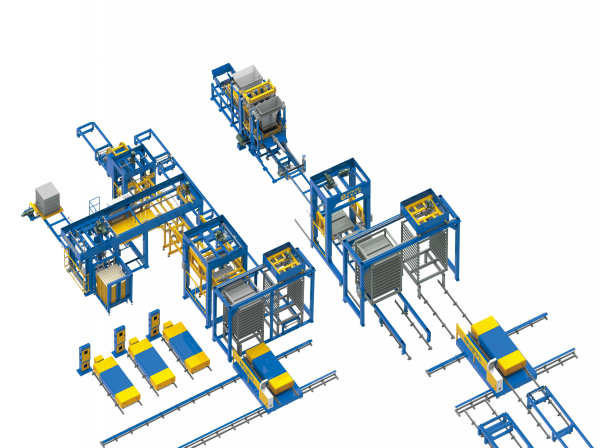

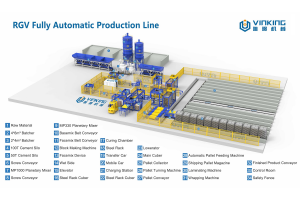

We have developed and produced different types of block making machine to suit different customer’s requirements. Automatic RGV transfer car system can be with or without steel curing rack to improve the block making process and provide a better solution for our customers to produce higher standard concrete products.

Design: Determining the product, Confirming mould drawing, Preparing the material.

Production: Processing, Assembling, Heat treatment, Welding, Matching, Painting, Packing.

Quality Checking: Quality inspection of work-in-process, Quality inspection of finish product.

lNo Shipping Pallet

lForklift Hole

lAuto Cubing With Rotation

lLess Damage Rate

lLaser Position

lFlexible Pallet Size

lFrequency Control

lStable Cubing

lServo Motor

1.Batcher

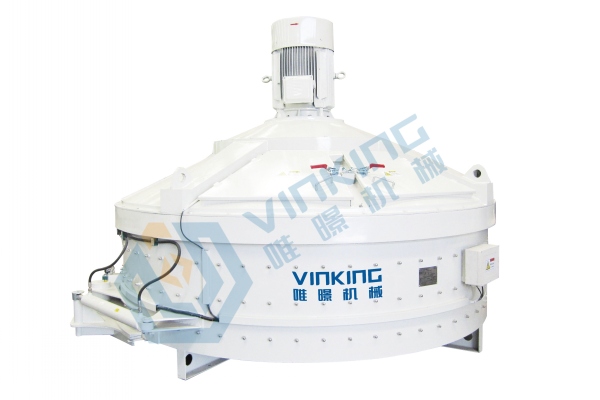

2.Planetary Mixer

3.Automatic Pallet Feeding Device

4.Water Curing Lifting Device

5.Strength Testing Machine

6.Four Side Clamp, Two Side Clamp With & Without Rotation

7.GMT Pallet With & Without Steel Reinforcement (Galvanized Steel)

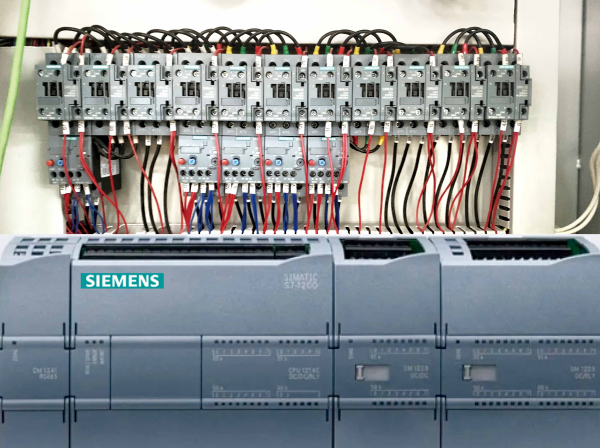

1.Machanical Parts: Siemens, SEW, ABB, HARDOX, Air TAC, Oli-Wolong, etc.

2.Electric Parts: Siemens, Schneider, Omron, ABB etc.

3.Hydraulic Parts: Taiwan Yuken, Italy Manuli, HAWE, Rexroth, etc.

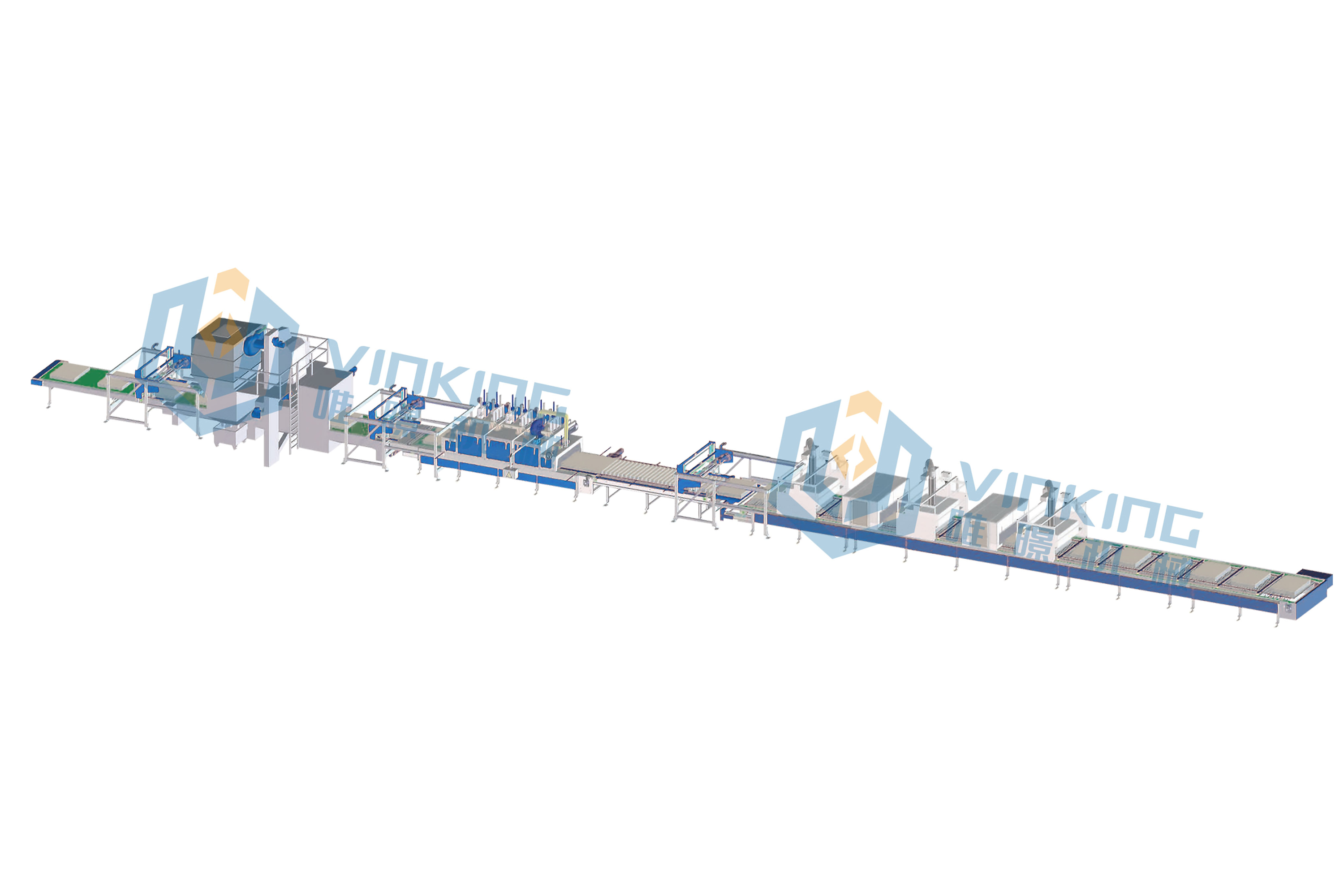

SURFACE TREATMENT PRODUCTION LINE

1 IR preheating station

2 Spraying – primer

3 IR heating station

4 Spraying – sealer

5 IR heating station

(Coating line modular extendable with IR and/or UV stations)

(Instead of spraying, roller coating is also possible) depending on the coating agents used)

- Core Technology

Core Technology:

Vinking Machinery independently develops and produces different models of concrete block making machine adapted to different capacity requirements for investment, with automatic RGV transfer car system, new energy transfer with steel curing rack, improving the block making process and providing more quality concrete product production solutions for our customers.

1.Main Frame Adopt Germany Standard

2.Efficient Vibration Technology

3.Fast Feeding Car

4.Intelligent Frequency Conversion Technology

5.Siemens Control System

6.Servo Hydraulic System

- Service

Service:

18 oversea offices in 6 global market:

Africa Region: Egypt, Nigeria, Kenya, South Africa

Middle East: UAE, Saudi Arabia, Iraq

South Asia: India, Pakistan

Asia: Philippines, Vietnam, Thailand, Indonesia

Latin America: Mexico, Brazil

Europe and America: UK, USA, German

Fujian Vinking Machinery Co.,Ltd, dedicated to high-end concrete manufacturing machinery, excellence, established to serve more than 30 provinces and area in China.

Integrated R&D and production services by an elite team

Pre-sales service, in-sales service and after-sales service

All-round service for customers

- News

News:

Watch out for more of Vinking's global exhibitions and come and see the latest innovations at Vinking.

Vinking is working with many partners around the world to build a new intelligent ecosystem that will drive technological breakthroughs and innovation in the precast concrete industry.

Follow the industry news, never stop on the road of exploration and innovation. - Contact Us

Contact Us:

Fast communication with customers and zero distance service, just to work with you to win together.

Respecting talent, retaining talent, using talent, creating first-class talent, creating first-class enterprises.

If there is anything we can do for you, most welcome to contact us by whats’ app, E-MAIL etc 24 hours. We will reply to you as soon as possible.