ICCX EURASIA 2023

ICCX EURASIA 2023INTERNATIONAL CONCRETE CONFERENCE & EXHIBITIONDecember 06-072023 Amaty, KazakhstanVisit us at booth#40

Fujian Vinking Machinery Co.,Ltd is located in Quanzhou, the first East Asian cultural capital. We are committed to forming, curing and packaging high end concrete product. We have gathered the latest technology and productivity from home and abroad to provide customers with best solutions.

The unity of “Vinkinger” and our resilience have led to the establishment of a team of professional engineers who have gradually developed our own core technology with our strong research and development capabilities and innovative spirit.

With a legacy of glory, Vinking continues to develop with the recognition of the industry and society.

Forest Press Hydraulics Hermetic Press

Europe's leading hermetic press machine, FOREST PRESS HYDRAULICS, has been bringing its products and services from the UK to continental Europe to the world since 1984, specialising in hermetic press wet mix kerb/slab making, a heavy duty machine designed ahead of its time and proven in different climatic conditions around the world.

1. VK600 automatic block making machine is an economical machine developed and produced by Vinking Machinery. It uses 360° fast feeding system, shorter forming cycle and higher production efficiency.

2. VK900 automatic block making machine forced synchronous vibration system can be adjusted through Siemens frequency conversion technology, vibration excitation force, the use of steel transmission, no kinetic energy loss and can ensure accurate synchronization, less energy consumption, better vibration effect.

3.VK1200 automatic block making machine combines the advantages of VK900 and VK600, and by optimising the design, the mould is easier to combine for the number of modules and pendulum blocks for the production of products, and is more flexible for the matching mode of the production line, which can be an economic mode with a selected layout, and also suitable for the fully automatic production line mode.

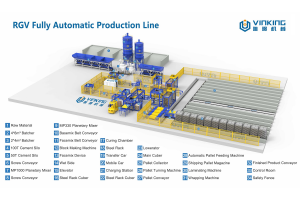

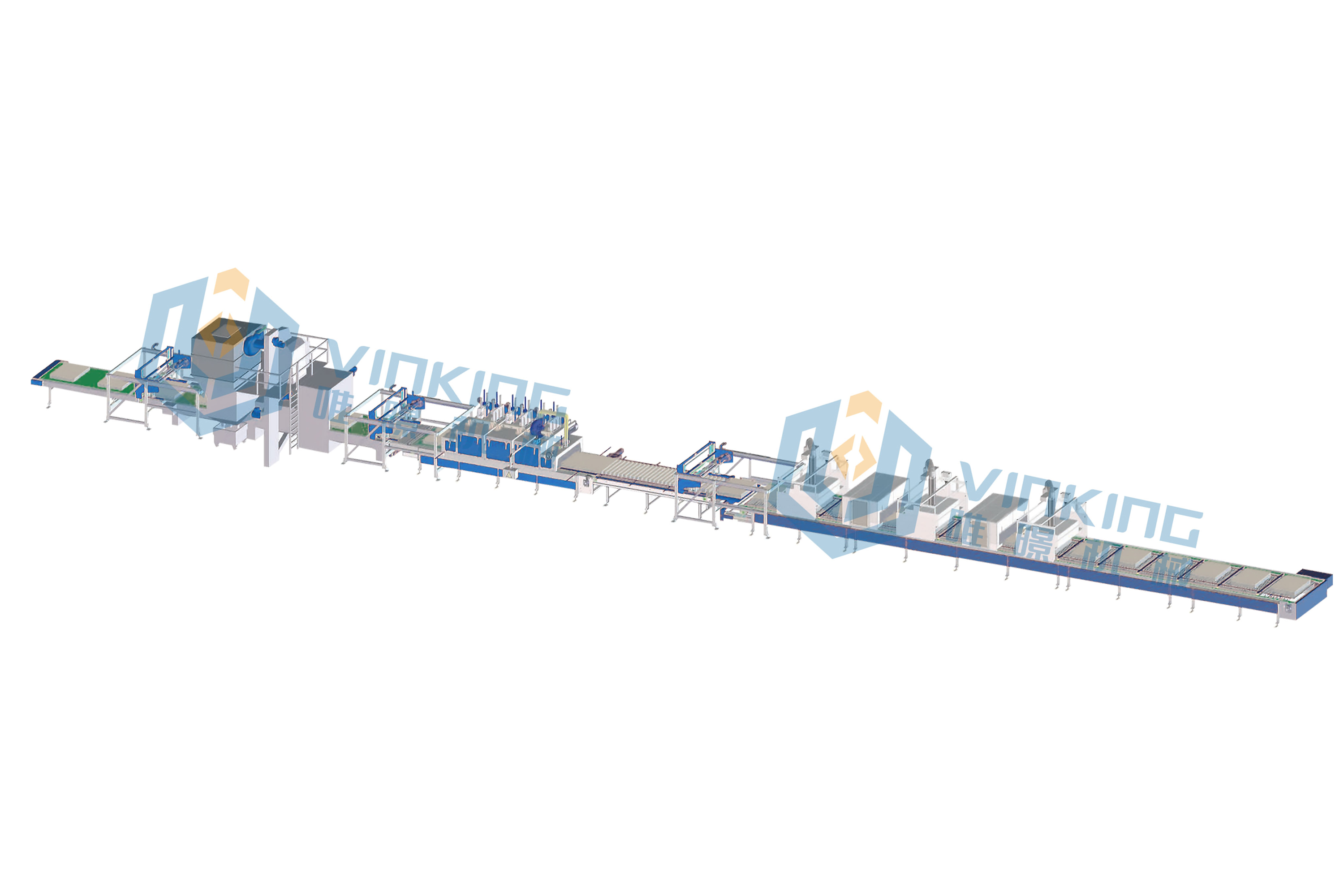

We have developed and produced different types of block making machine to suit different customer’s requirements. Automatic RGV transfer car system can be with or without steel curing rack to improve the block making process and provide a better solution for our customers to produce higher standard concrete products.

Design: Determining the product, Confirming mould drawing, Preparing the material.

Production: Processing, Assembling, Heat treatment, Welding, Matching, Painting, Packing.

Quality Checking: Quality inspection of work-in-process, Quality inspection of finish product.

lNo Shipping Pallet

lForklift Hole

lAuto Cubing With Rotation

lLess Damage Rate

lLaser Position

lFlexible Pallet Size

lFrequency Control

lStable Cubing

lServo Motor

1.Batcher

2.Planetary Mixer

3.Automatic Pallet Feeding Device

4.Water Curing Lifting Device

5.Strength Testing Machine

6.Four Side Clamp, Two Side Clamp With & Without Rotation

7.GMT Pallet With & Without Steel Reinforcement (Galvanized Steel)

1.Machanical Parts: Siemens, SEW, ABB, HARDOX, Air TAC, Oli-Wolong, etc.

2.Electric Parts: Siemens, Schneider, Omron, ABB etc.

3.Hydraulic Parts: Taiwan Yuken, Italy Manuli, HAWE, Rexroth, etc.

SURFACE TREATMENT PRODUCTION LINE

1 IR preheating station

2 Spraying – primer

3 IR heating station

4 Spraying – sealer

5 IR heating station

(Coating line modular extendable with IR and/or UV stations)

(Instead of spraying, roller coating is also possible) depending on the coating agents used)

Vinking Machinery independently develops and produces different models of concrete block making machine adapted to different capacity requirements for investment, with automatic RGV transfer car system, new energy transfer with steel curing rack, improving the block making process and providing more quality concrete product production solutions for our customers.

1.Main Frame Adopt Germany Standard

2.Efficient Vibration Technology

3.Fast Feeding Car

4.Intelligent Frequency Conversion Technology

5.Siemens Control System

6.Servo Hydraulic System

18 oversea offices in 6 global market:

Africa Region: Egypt, Nigeria, Kenya, South Africa

Middle East: UAE, Saudi Arabia, Iraq

South Asia: India, Pakistan

Asia: Philippines, Vietnam, Thailand, Indonesia

Latin America: Mexico, Brazil

Europe and America: UK, USA, German

Fujian Vinking Machinery Co.,Ltd, dedicated to high-end concrete manufacturing machinery, excellence, established to serve more than 30 provinces and area in China.

Integrated R&D and production services by an elite team

Pre-sales service, in-sales service and after-sales service

All-round service for customers

Watch out for more of Vinking's global exhibitions and come and see the latest innovations at Vinking.

Vinking is working with many partners around the world to build a new intelligent ecosystem that will drive technological breakthroughs and innovation in the precast concrete industry.

Follow the industry news, never stop on the road of exploration and innovation.

Fast communication with customers and zero distance service, just to work with you to win together.

Respecting talent, retaining talent, using talent, creating first-class talent, creating first-class enterprises.

If there is anything we can do for you, most welcome to contact us by whats’ app, E-MAIL etc 24 hours. We will reply to you as soon as possible.

As the country's infrastructure grows stronger, so does the speed of urban metabolism. Large numbers of old buildings have been demolished to make way for grander, more beautiful structures. At the same time, construction waste has been created, which has effectively become a metabolic product that hinders urban development.

The current volume of construction waste in China is large, but the utilisation rate is less than 10%. With the shortage of natural sand resources and rising sand prices, the resourceful utilisation of construction waste has become a new investment hotspot, with Beijing, Henan, Hunan, Shandong, Shaanxi, Anhui, Guizhou and Guangdong issuing policies to encourage the recycling and reuse of construction waste.

Firstly, the construction waste is initially cleaned up, sorted out into recyclable steel and wood, then the bricks and stones, cement and concrete blocks are crushed into aggregates, sieved to remove impurities and form the raw materials of building materials with certain particle size requirements. Then add cement and fly ash and other auxiliary materials to the raw materials according to the grading design requirements, add some water and then mix to form different building products and road construction products, these products can completely replace ordinary sand and gravel materials for road base.

Secondly, the recycled aggregates produced from waste bricks and tiles are used to produce recycled bricks, blocks, wall panels, floor tiles and other building material products through brick making machines. These recycled bricks are extremely environmentally friendly and contain ground materials such as ecological permeable bricks, poured permeable bricks and permeable kerb bricks, which are widely used in squares, footpaths, slow lanes, open squares, gardens, slope protection, foundation protection, highways and overpasses.

Thirdly, the residue can be used for road construction, pile fill, foundation base, etc.

Fourth, for abandoned timber-based construction waste, timber that has not been significantly damaged can be directly reused to rebuild buildings, and severely damaged wooden components can be used as raw materials for wood recycling panels or paper making, etc.

Fifth, waste road asphalt mix can be used directly for recycled asphalt concrete in appropriate proportions.

Sixth, waste road concrete can be processed into recycled aggregates for the preparation of recycled concrete.

Seventh, waste steel, scrap steel and other scrap metal materials can be directly reused or processed back to the furnace.

Eighth, the construction waste sorting, crushing the remaining silt, stone powder as raw materials, adding a variety of other wastes (mainly including sewage treatment plant sludge, wineries, food factories, waste residue) and peat soil trace elements, according to a certain quality ratio, mixed and mixed to make recycled construction waste planting soil, in addition to the characteristics of natural soil, but also has high fertility, good air permeability and strong water retention characteristics. It is reported that the soil characteristics of the recycled planting soil meet and exceed the national soil standards and meet the fertility requirements of high-yielding farmland, as demonstrated by relevant analyses.

Construction waste recycling "three-step process"

Step 1: from site to plant landfill is no longer the first choice

For 30 years, construction waste has been destined for low-lying areas and pits on the outskirts of the city, either naturally or as a result.

Over time, the problem of construction waste taking up land has come to the fore, and as legal landfill sites become fewer and further between, it becomes increasingly difficult to dispose of construction waste; more importantly, landfills can cause varying degrees of pollution to the air, soil and groundwater.

It is against this background that the concept of resource-based disposal has started to appear frequently in policy documents and in the public eye.

Construction waste is not really completely useless rubbish; on the contrary, it contains concrete blocks, mountain stones, steel bars, etc., which can be recycled. The process of turning what people think is waste into a product that can be used again is called resourceful disposal.

Step 2: From incoming to outgoing earth concrete gold in its place

The construction waste is pulled into the plant and the pre-sorting and crushing unit begins its operations: under the treatment of dust and fog cannons, workers inspect the surface of the construction waste for useless components visible to the naked eye, such as thatch, rubber, wood and plastic; in the open space next to it, hooks replaced with drills crush the oversized construction waste; and forklifts push the appropriately sized construction waste into the entrance of the buried jaw crusher. To reduce dust, a dust extraction device can be installed at the crusher entrance.

The logic of the whole line is actually to separate the construction waste by components and prepare the high value-added components into reusable raw materials: after the first crushing, the belt sends the material up and through a de-ironer to separate out the large pieces of metal (mainly steel) for recycling; then it passes through a heavy-duty sieve to screen out the soil, which goes directly into the slag bin; after the soil is screened the material goes into a positive pressure wind separator, which uses wind to blow out some of the larger The material goes into the positive pressure wind separator, where the wind blows out some of the lighter materials, such as plastic, wood chips and paper."

After the first round of crushing and screening, the material is already relatively clean and homogeneous, basically concrete blocks or bricks. Immediately afterwards, it enters the impact crusher, where it is repeatedly rotated and beaten into particles ranging from a few millimetres to tens of millimetres in diameter, i.e. recycled aggregates.

Step 3: From plant to site road park meet again

The recycled aggregate has been produced, where will it go?

Sand and gravel is one of the most important materials in construction. Paving of road sub-base, preparation of mortar, production of concrete and bricks all require sand and gravel to take on the role of skeleton and filler in them. However, sand and gravel resources are limited and over-exploitation poses an ecological hazard, whereas recycled aggregates can be used instead of sand and gravel, provided that technical standards are met.

Even if it does not work with other materials such as cement, recycled aggregates can work on their own: in garden landscaping, the ground is first undulated with coarse aggregates, covered with a layer of organic soil, then a layer of fine aggregates, then a layer of organic soil, and the top layer is planted with trees and grass, creating a sponge-type soil that is both permeable and water-storing.

Although the volume of construction waste is large, it is basically "buildable material" that can be transformed. However, the overall concentration of the recycling industry itself is low, and the pattern of "low, small and scattered" is difficult to change in the short term, so the construction waste "collection-transportation-use" system is still a long way from maturity. There is still a long way to go before the system is mature. However, with the improvement of people's environmental protection concept, as well as the government's guidance to designers and constructors, there will be a wide market space for the application of resource-based products, and the treatment of construction waste will naturally be smoother.

ICCX EURASIA 2023

ICCX EURASIA 2023INTERNATIONAL CONCRETE CONFERENCE & EXHIBITIONDecember 06-072023 Amaty, KazakhstanVisit us at booth#40

Germany Ha-Be officially authorizes Vinking Machinery as EXCLUSIVE DISTRIBUTOR in CHINA.

Ha-Be Betonchemie GmbH has appointed Fujian Vinking Machinery Co., Ltd as its EXCLUSIVE DISTRIBUTOR for Concrete admixtures & impregnati···

MOB:+86 136 7590 9717

TEL:+86 595 8679 9877

FAX:+86 595 8679 9877

E-MAIL:vinking@vkmachine.com

ADD:NO.17, BINJIANG ROAD, XIAMEI MECHANICAL EQUIPMENT INDUSTRIAL BASE, NAN’AN, QUANZHOU, FUJIAN, CHINA

Copyright @ 2021 . Fujian Weiyu Machinery Co., Ltd .